What best car diagnostic tool for benz ?

For Mercedes-Benz vehicles, selecting a diagnostic tool that can effectively interact with the brand’s sophisticated systems is crucial. Here are some of the best diagnostic […]

For Mercedes-Benz vehicles, selecting a diagnostic tool that can effectively interact with the brand’s sophisticated systems is crucial. Here are some of the best diagnostic […]

Here’s a comprehensive FAQ for the Star Diagnostic Tool, specifically focusing on its application with Mercedes-Benz vehicles: What is a Star Diagnostic Tool? The Star […]

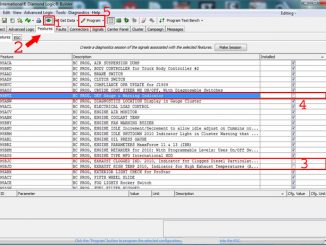

On this page we will inform You how to disable regen light & DEF gauge on International vehicles. Sometimes after delete, the regen light & […]

VCM II VCM2 For Ford V128 And Mazda V128 Diagnostic Tool 2 In 1 VCM II Function: * Automatic vehicle recognition * Read & Clear […]

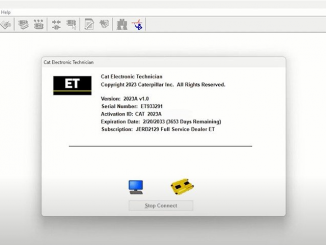

Caterpillar electronic technician 2023A (replaces CAT ET 2022C, 2022B, 2022A, 2021A, 2019C) with WinFlash future is an updated version of the caterpillar dealer diagnostic software […]

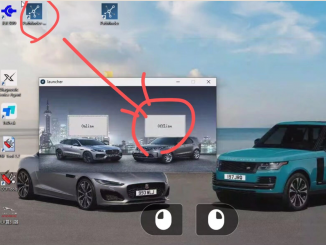

Hello,Recently so many friends received the JLR Pathfinder and SDD Diagnostic tool,and they asked the pathfinder and SDD Password,how to solve this problem? JLR DoIP […]

Here comes the problem: I purchased a flood damaged 2019 Ford F150 with a bricked Body control module that could not be cloned. So far […]

This illustrations how you guide on how to repair Perkins 1106D electric power generation (EPG) engine low power and/or rough running with CID 0001 FMI […]

JCB Backhoe Loader 3CX steering column can be tilted to improve operator reach and comfort levels. This type of assembly is refered to as a […]

How to cut this JMA key on Xhorse Dolphin XP-005? I can decode by eye but tip is different to basic nec/bga blades. Insert nec/bga […]

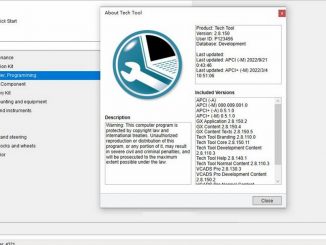

What is Tech Tool? Tech Tool is a tool that supports the repair and diagnostic process, developed to make the work in the workshops easier […]

What is Caterpillar ET? Caterpillar Electronic Technician (Cat ET) is diagnostic software required to communicate, diagnose and service electronically controlled Caterpillar engines and machines. When […]

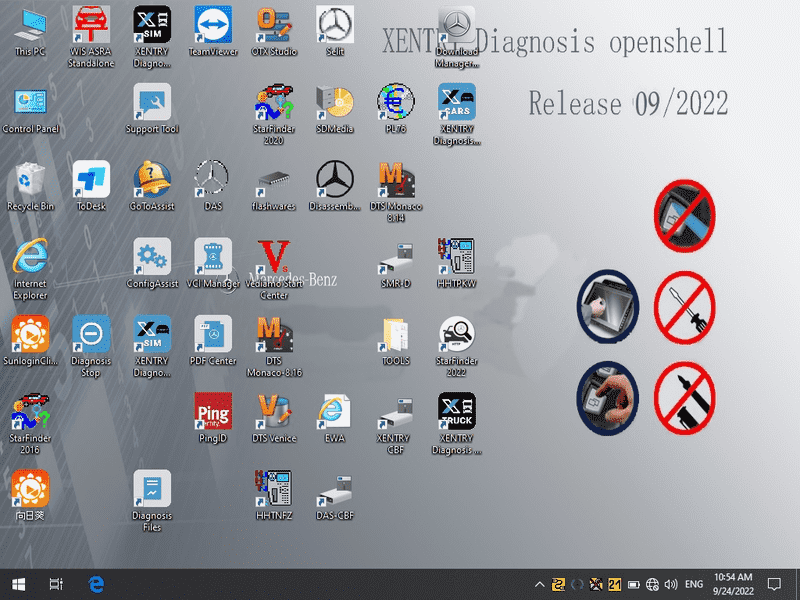

MB Star diagnostic Xentry 09.2022 release is now available,so far everything works as before …..It is confirmed working perfectly with 12v 24 Mercedes car, Bus, […]

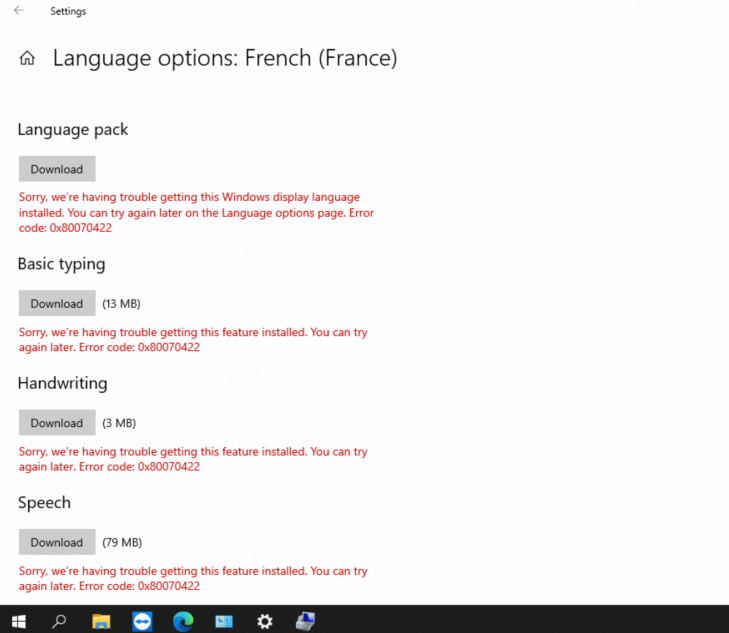

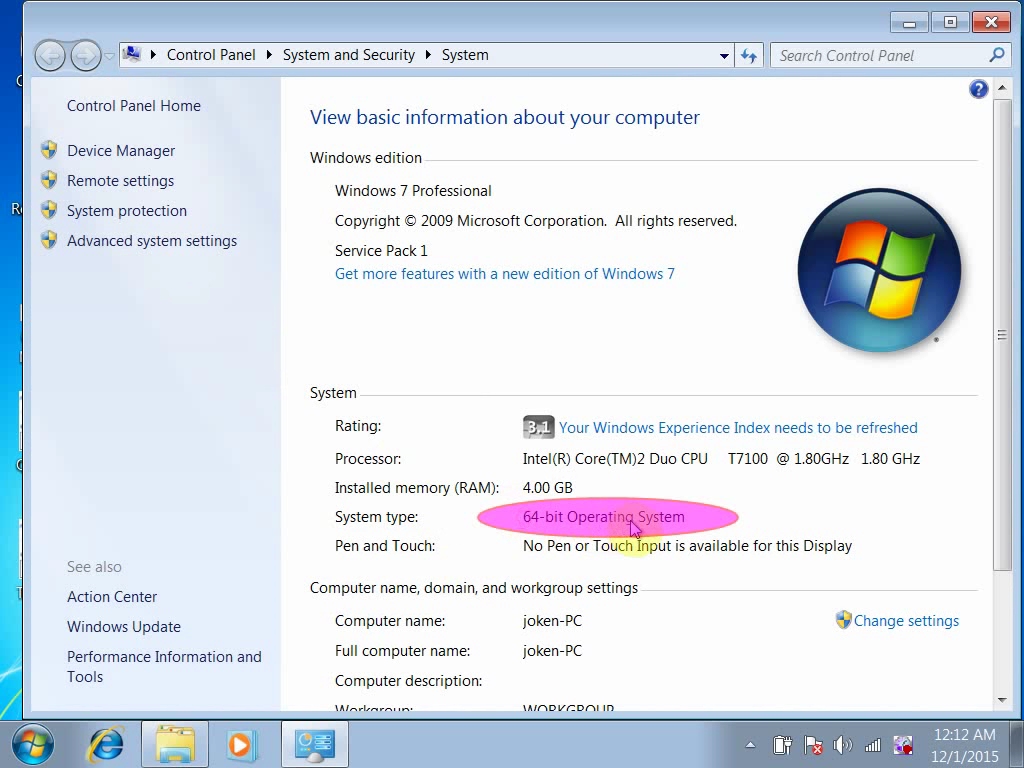

Problem 1 : Having trouble getting this Windows Display Language Installed Steps how to fix it : Open the desktop “TOOLS” file –> Windows Update […]

Here are many GM GDS software versions on the Internet, and the different versions need to use compatible interfaces, the installation methods are different, so […]

Copyright © 2025 | WordPress Theme by MH Themes